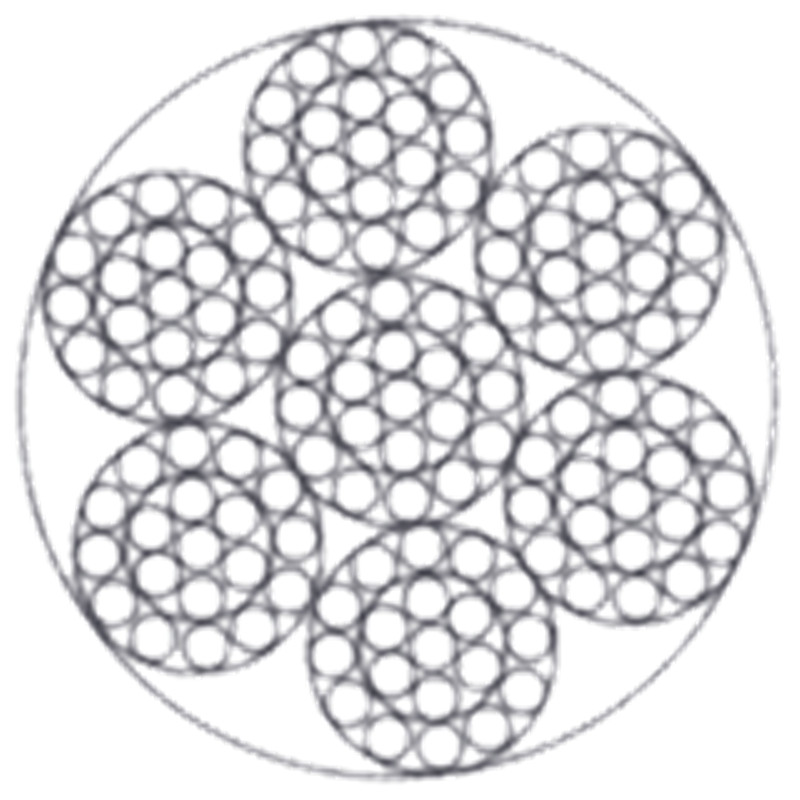

Karfe Waya Igiya gano Igiyar waya ɗaya ce daga cikin mahimman sassa na crane, kuma aikin amincin sa yana shafar aikin gabaɗayan crane.Don haka, a cikin aikin yau da kullun, dole ne mu yi aiki mai kyau a cikin binciken igiyoyin waya, kawar da haɗarin ɓoye cikin lokaci, da tabbatar da aminci.

1. Duban bayyanar:

1) Bincika bayyanar fashe, nakasawa da lalata;

2) Duba ko saman yana santsi kuma har ma;

3)Duba lamba da tsayin wayoyi da suka karye (gaba ɗaya ƙasa da 2 a kowace mita).

2. Gwajin juzu'i:

Gwajin juzu'i shine a cire samfurin tare da tsayin 10mm zuwa nisa na 100 ~ 150mm daga ƙarshen gwajin, sannan a ja samfurin zuwa matsayin asali daga nesa na 50mm daga ƙarshen gwajin a wani takamaiman gudu.

Ya kamata a kula da abubuwan da ke gaba yayin gwajin tensile:

1) Kafin a auna karfin, karfen da za a duba sai a saki jiki na tsawon mintuna 5 sannan a cire datti kamar mai da kura;

2) Lokacin auna ƙarfin, ya kamata a ƙara ƙarfin a hankali har sai ƙimar da aka ƙayyade;

3) Bayan kowane ma'auni, mai rikodin ya kamata a sake saita shi zuwa sifili kafin auna na biyu;

4) Idan ya zama dole don auna sakamako da yawa, mafi girma zai yi nasara.

3. Duba adadin wayoyi da suka karye:

Adadin wayoyi da aka karye suna nufin kashi (%) na filaments waɗanda diamitansu bai kai ko daidai da diamita na ƙima ba, wanda ke nuna adadin abubuwan da ba na ƙarfe ba a cikin tsarin ciki naigiyar wayada darajar sawa.

4. Duban gajiyawar rayuwa:

Bayan an ɗora takamaiman adadin daidaitattun fayafai a kan jig kuma an gyara su, lanƙwasa kowane haɗin zobe akan daidaitaccen ɓangaren diski akai-akai bisa ga ƙayyadaddun adadin lokuta da tazara, sa'an nan kuma cire kusoshi masu haɗawa na kowane daidaitaccen sashi ɗaya bayan ɗaya. kuma haɗa su.Saka su a cikin kofuna na musamman masu alama da ma'auni (kofuna masu auna daidai da ƙayyadaddun igiyoyin ƙarfe da za a auna), sa'an nan kuma sanya waɗannan kofuna a cikin yanayin da zafin jiki na 20± 1 ° C na fiye da 3 hours. don lissafta saitin kulli.Ƙimar rayuwar gajiyar diski.

5. Duban lalata:

Hanya ce mai sauƙi don gwada ingancin galvanized Layer ta hanyar nutsewar acid.Kauri na galvanized Layer jiƙa a cikin maganin sulfuric acid gabaɗaya tsakanin 0.15 zuwa 0.2 mm.Yana nuna cewa wannan tsari na galvanizing bai cancanta ba ko yanke sasanninta.

6. Gwajin karkatarwa:

A amfani, an gano cewa wasu masu amfani za su yi amfani da wasu ƙananan kayan aiki don maye gurbin ƙarfe mai inganci don samar da ƙugiya ko majajjawa don adana farashi.Wannan ba kawai zai shafi rayuwar sabis na samfurin ba, har ma yana haifar da haɗari mai girma na aminci.Don haka mu Lokacin siye, dole ne mu zaɓi samfuran inganci na samarwa na yau da kullun don tabbatar da amincin kanmu da dukiyoyinmu!

Lokacin aikawa: Jul-22-2022